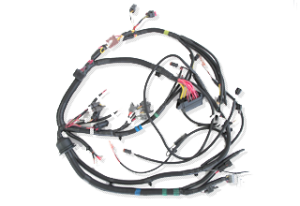

Wiring harnesses, electric cables are tied up in a bundle, is for electric supply and signal transfer.

We have a high reputation for technological excellence and strong experience by construction and farm machinery manufacturer all over the world.

For producing harnesses, we do all the work from design to production consistently.

Taking state-of-the-art technology, we have a strong system for diversified computerization to be able to flexibly deal with.

Having the advantage of manufacturing abroad, we can provide a friendly cost to customers in accordance with the changes in times.

Not only “lower cost”, but also “high quality” and “reliable delivery date” are provided.

We set a production schedule and procure parts adjusting the delivery date.

We have appropriate stocks taking into account quick deliveries.

We put the all information about drawing data from customers into our own system and we make up an estimate based on drawings and the data from the system.

We follow the order from the system and do wire cutting and terminal applying.

Using jigs, we assemble processed cables with customers’ specs.

Using dedicaded continuity checker, we check all products how it follow the instruction.

We check size, exteriors, and attached components by visual inspection how it follow the instruction.